Metaverse

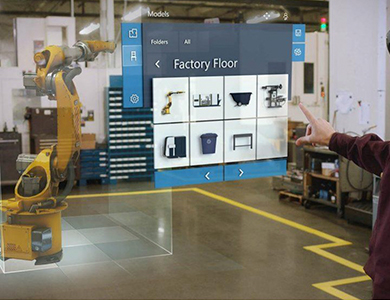

XR technology that simplifies content production through systematic system construction and operation and reduces work time and cost by intuitively understanding the work process.

XR Convergence content construction effect

We design and implement XR technology by reflecting industrial site requirements for each local industry sector.

-

Reduced facility down-time by introducing a

Reduced facility down-time by introducing a

non-face-to-face collaboration system -

Reduced safety accidents and tracking accident

Reduced safety accidents and tracking accident

history through long-distance monitoring -

Reduced working time and cost with

Reduced working time and cost with

real-time remote system -

Content can be utilized in

Content can be utilized in

diverse devices

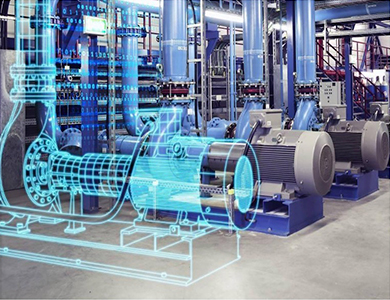

Main contents of XR-based facility diagnosis solution for facility control and safety in petroleum and chemical industry

-

Plant site visualization

- Area Target and Mark based facility and location recognition

- Tank content capacity visualization

- Visualization of plant tag information such as temperature, RPM, flow rate, etc

-

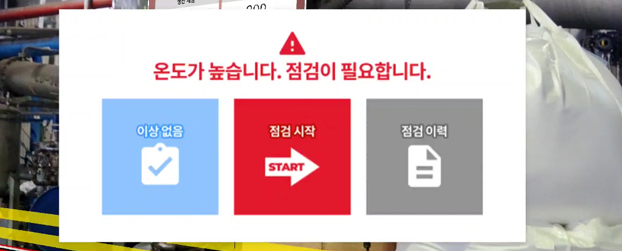

XR facility predictive maintenance

- Temperature and RPM sensor information monitoring

- Emergency stop through PLC control signal (administrator)

- Abnormal pattern detection manager notification and diagnostic support

-

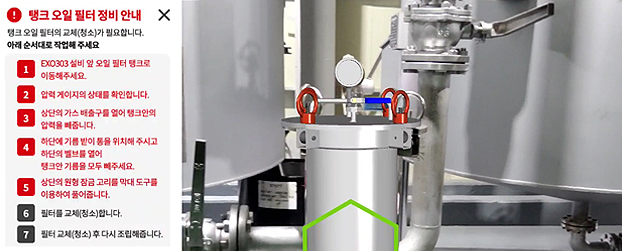

XR Maintenance tutorial

- Guidance through maintenance location navigation function

- Maintenance sequence and method guidance through 3D model animation

- Providing video tutorials using Expert Capture

-

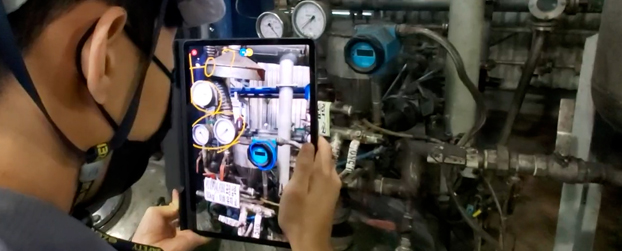

Augmented reality remote collaboration

- Support for collaboration of field workers and remote experts using Remote Video Call

- Utilization of Vuforia Chalk based augmented screen sharing technology

- History management based on videos and images of maintenance contents

XR convergence content concept diagram and process

XR convergence content uses field

XR convergence content main features

-

Remote on-site monitoring

Remote monitoring of dangerous areas

Reduction of work required time

Reduction of safety accidents -

Augmented reality quality inspection

Improvement of quality inspection accuracy

Improvement of reliability of inspection result records

Part acceptance inspection

Shipment inspection -

Work productivity improvement

Operational efficiency

Service cost reduction

Work required time reduction

Safety accident reduction -

Predictive maintenance solution

Visualization of device abnormal condition monitoring

Resolution of abnormal conditions

On-site maintenance operation inspection -

Non-face-to-face collaboration

Remote expert support

Community error prevention -

Visualization for field workers

Real-time data and trend visualization

Proof of work through on-site inspection

Safety information

Digital manual